Turning Tools Market Future Growth, Key Players, Opportunities and Forecast by 2031

The turning tools market is growing at a CAGR of 8.3% from 2022 to 2031

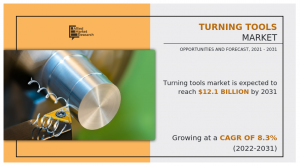

PORTLAND, OREGON, UNITED STATES, November 21, 2023 /EINPresswire.com/ -- The global turning tools market size was valued at $5.3 billion in 2021, and is projected to reach $12.1 billion by 2031, growing at a CAGR of 8.3% from 2022 to 2031.

The Turning Tools Market scope consists of a replaceable insert in the body of the tool. It involves a fixed and non-rotating cutter as in turning, the workpiece spins instead of the tool. The tool inserts vary in shape, material, coating, and geometry. These tools can be round in shape to increase the strength of the edges; tools in diamond shape allow sharp points to cut into fine features; square shaped tools maximize the number of separate edges to change it if it wears out.

Request for Sample Report (Get Full Insights in 205 PDF Pages) @ https://www.alliedmarketresearch.com/request-sample/17442

Top Leading Companies: WNT Tools India Pvt Ltd, Shanghai Tool Works Co. Ltd, Applitec Moutier SA, Ingersoll Cutting Tool Company, ISCAR LTD, Aloris Tool Technology Co. Inc, Dormer Pramet, Seco Tools, Beijing Worldia Diamond Tools Co.Ltd, Walter Tools, Dorian Tool International Incorporated, Danobat Group, Kennametal Foundation, ALESA AG, Hanjiang Tool Co., Ltd, Ceratizit, Kyocera Unimerco.

Rise in global population significantly increased the demand for private and public vehicles for transportation purposes. According to the U.S. Department of Transportation, as of 2020, there were as many as 274 million vehicles on the roads in the U.S. This large number of on-road vehicles has significantly increased the number of garages and service centers, as they are vital for maintaining safe working condition of vehicles. Increase in number of garages and service centers, thereby creating a demand for turning tools market outlook.

The turning tools market stands at the intersection of precision engineering and technological innovation, playing a crucial role in shaping the landscape of modern manufacturing. This dynamic sector is witnessing a surge in demand as industries across the board seek advanced solutions for machining and turning processes. Key drivers of this growth include the adoption of cutting-edge materials such as ceramics and carbides, the integration of IoT technology for real-time monitoring, and the embrace of additive manufacturing techniques.

As industries increasingly prioritize efficiency and quality, turning tools are evolving to meet these demands, offering solutions that not only enhance productivity but also contribute to the ongoing transition towards Industry 4.0. Challenges, such as environmental concerns and the need for a skilled workforce, are being addressed as opportunities for the market to further innovate and refine its offerings.

Buy This Research Report @ https://www.alliedmarketresearch.com/checkout-final/19f16a4af0f72530a368f59925fd1106

These are extensively used in garages and auto service centers for repair and maintenance of vehicles to extend the vehicle life. Furthermore, turning tools are cost-effective and have minimal maintenance requirements, making them ideal for use in small industries. The turning tools market plays a pivotal role in shaping the future of industries by providing cutting-edge solutions for machining and turning processes. As technology continues to advance, the turning tools sector undergoes its own transformation, offering innovative tools that redefine precision and productivity.

Turning tools are now being manufactured with advanced materials such as ceramics, carbides, and cubic boron nitride (CBN). These materials offer enhanced durability, heat resistance, and wear resistance, resulting in longer tool life and reduced downtime. The integration of IoT (Internet of Things) technology into turning tools is a game-changer. Smart tools provide real-time data on tool performance, temperature, and wear. This data enables predictive maintenance, minimizing unexpected downtime and optimizing production schedules. Additive manufacturing is revolutionizing the production of turning tools. 3D printing allows for the creation of complex geometries and customized tool designs, opening up new possibilities for efficiency and performance.

The turning tools market is poised for continued growth as industries demand higher precision and efficiency. As technology continues to advance, we can expect further innovations, such as the integration of artificial intelligence and machine learning, to redefine the capabilities of turning tools. The turning tools market is at the forefront of the manufacturing revolution, driving advancements that shape the future of precision engineering. As industries embrace these innovations, the market is set to play a crucial role in transforming the way products are manufactured across various sectors.

Enquiry Before Buying @ https://www.alliedmarketresearch.com/purchase-enquiry/17442

David Correa

Allied Analytics LLP

+ +1 800-792-5285

email us here

Visit us on social media:

Facebook

Twitter

LinkedIn

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.